- (86)13915349938

- yiru.wang@wxfengwei.com

Select Your Industry

With more than 3200 machines present in variety of industries, in more than 30 countries around the world, Fengwei is positioned as a world leader in the field of welding automations. We offer top-of-the-range solutions based on innovatoin, adapted to each demand in each industry.

-

Petrochemical Industry

Welding rotators and welding manipulator bring a cost effective production line into the p...

-

Environmental Protection

Aim of 2030 carbon neutral intensifies the demand of renewable energy construction. Onshor...

-

Steel Structure

Steel structure is an indispensable material type in construction industry. Strict standar...

-

Power Tower

Steel made power lever and communication poles increasingly replace the traditional cement...

Choose Your Needs

-

Welding Rotator

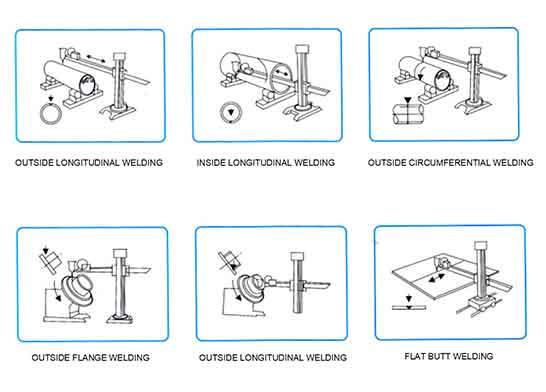

A welding rotator is a piece of auxiliary welding gear. It uses fric...

Read more

-

Welding Positioner

Fengwei Machinery has a wide variety of welding positioner for your ...

Read more

-

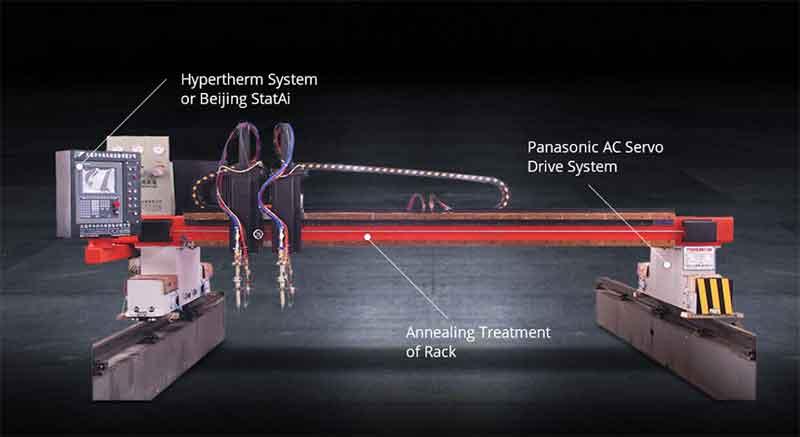

Welding Manipulator

Welding Manipulator is mainly used to complete Girth Welding of Circ...

Read more

-

Turning Rolls

Turning rolls, also called welding rotator, is a common welding auxi...

Read more

-

Pipe Welding Rotator

The pipe welding rotator plays a vital role in the automatic product...

Read more

-

Column and Boom

Column and Boom, (also called C&B) are mainly composed of a column, ...

Read more

Talk To Us

Reach us for free technical proposal, e-Catalogue, Price List and Field Videos.

Get Best QuoteProduction Line Display

Fengwei integrates R&D, design, and manufacturing 3 automatic production lines, which are wind tower production line, beam production line, and box beam production line.

In H Beam Welding Line is a highly automated H-beam steel production line. It aims to reduce and reduce the frequency of driving. By adopting automatic equipment such as conveyor rollers, turning machines and steel moving machines, the welding process H-shaped steel is conveyed, turned and moved, which significantly improves the user's production efficiency.

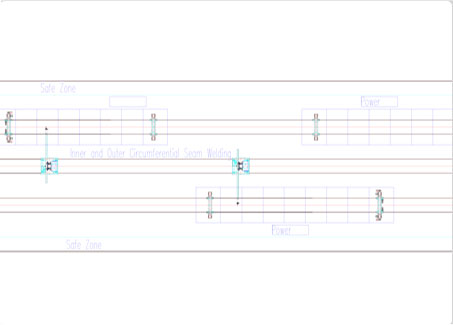

Wind Tower Production Line is mainly divided into two welding forms, one is seam weldment of single wind tower.This working area mainly consists of welding manipulator and lead screw welding rotator to complete the internal and external longitudinal seam welding of tower drum and the assembly and welding of bottom flange.The other is seam weldment among multiple wind towers.This working area adopts a completely different idea from the traditional method. We use the traveling welding rotators to realize the logistics transmission of the tower in the workshop

- Wind tower production line

- H Beam Welding Line

- Box Beam Production Line

-

Replacing the traditional way of fabricating wind tower lines, Fengwei's automation and solution helps you to save 50% labour cost and boost 70% work flow efficiency. With years of the field experience, we offer you customized layout of the whole fabrication flow in the field from single wind tower to a grouped wind tower line by considering the concept of "safety, efficiency and economy".

-

H-beam production line is specially designed and developed for automating the production process of beam steel strucuture, widley used in building and bridge construction. It aims to bost operation efficiency, by applying automatic equipment such as h beam assemblying machine, beam welding line, beam straightening machine and automatic transmission devices of conveying roller table, turnover machine and steel moving machine. Such beam production line largely helps to increase the output of h beam/i beam/tapered beam.

-

Steel Box Girder Pruduction Line - Steel box girder is generally composed of cover plates, flanges, bottom and partitions, and is one of the main material types used in steel structure building construction. The components or parts are usually connected by welds, bolts or rivets. The box beam production line is the best choice to offer a stringent quality control and efficiency boost.

Rate Us

-

Kalyana

Fengwei's wind tower production line directly solves the production efficiency problem of the factory, and their after-sales service is excellent. Patiently tell us the instructions for the welding rotator and related machinery.

-

Lucy Ann

Fengwei is really a reliable partner. Their welding positioner is really powerful and can help me complete the production welding very well.

-

lucyan

The engineers of the welding rotator are really good. They can complete customized machinery according to our needs, and adjust the power we use to achieve the best solution.

-

Mot Lugaly

The equipment and quality required by the H Beam Welding Line production line are relatively high. For our factory, it is difficult to find a high-quality machinery supplier until we meet Feng Wei.

We Serve You

-

Customer Service

Our services do not stop at the point of sale. We offer our clients a full after-sales service. Our technical service team are available throughout the lifetime of your equipment. When service is required, our engineers are at on hand to assist.

-

Mechanical Maintenance

Regular mechanical maintenance is essential to ensure the smooth functioning of your equipment. Our Service Department is available to assist you with any queries or concerns you may have regarding your machines within 24 hours via phone or email.

-

Spare Parts & Consumables

Ensure optimum efficiency for your systems by using original spare parts and consumables. We stock spare parts and consumables that are readily available to for collection or delivery. Ensure optimum efficiency for your systems by using original spare par

-

Training

Visit our training facilities or train your staff on your site. Our instructors can show your operators on your machine how to cut and weld in the most efficient way.

News

-

Wed-05

2022

The architecture of beam straightener machine

Beam Straightening Machine

The frame of the beam straightening machine is a solid frame composite structure, which is a preloaded structure composed of a base, a column, an upper beam, a tie rod, and a nut. [Read More]

-

Wed-05

2022

Improve Weld Quality|Welding Rotator

welding rotator

The welding rotator belongs to welding auxiliary equipment. It is often used for cylindrical workpieces, inner and outer rings, or inner and outer horizontal welding. [Read More]

-

Wed-05

2022

FENGWEI Welding Equipment-Welding Positioner

Welding Positioner

The composition and application of the welding positioner are mainly to make the workpiece in the best welding position through the lifting, turning, turning, and other movements of the worktable.[Read More]

-

Wed-04

2022

How To Adjust The Beam Straightening Machine?

beam straightening machine

The beam straightening machine changes the straightness by extruding rods, etc. Through straightening rollers. Generally, there are two rows of straightening rollers, and the number varies. [Read More]

Frequently Asked Questions

-

Q: Fengwei Welding Positioner User Guide-Special for Welders

A:The welding positioners' placement concepts are the same for both large and tiny. The basic product is attached to the placement device and then moved through a mechanical process into a function that allows for the most straightforward welding and joining. The whole weldment is relocated when components or subassemblies are added to provide simple access to the welding positioner.

While the weldment is attached to a proper positioning tool, safety is increased. Cranes, chains, slings, and other non-rigid methods of moving an item can result in uncontrolled motion, which is potentially dangerous. Welders should not maneuver themselves beneath a likely heavy weldment without the assistance of a positioner, reducing the danger of damage from falling sparks, slag, or components.

Welder fatigue is reduced, protection is increased, weld quality is improved, and manufacturing floor space is saved when a weld is appropriately positioned, regardless of its dimensions. By utilizing a mechanical technique to move the weldment and placing the welding region in a comfortable position, Welders aren't forced to weld in inconvenient or out-of-function situations.

Even though many welders are trained to conduct overhead and vertical welding, down and welds generally need far less expertise, allowing even inexperienced welders to produce excellent results. Gravity assists the welder in a downward weld, leading in equal limbs on weldments, a cleaner beading area, and less cleaning and reconstruction time.

A welder may do semiautomatic welding that is both productive and ergonomically comfortable by combining a positioner with a welding strength source and a torch stand. Under the supervision of a desk-bound torch, the positioner holds the part and manipulates it. This torch might be equipped with a weaving motor to allow vibration to fill large gaps or v-grooves. Steady velocity and torch location raise the effectiveness and consistency of the weld.

Regardless of the size of both the weldment, welders must keep these five ideas in mind when choosing, working with, and servicing a positioner.

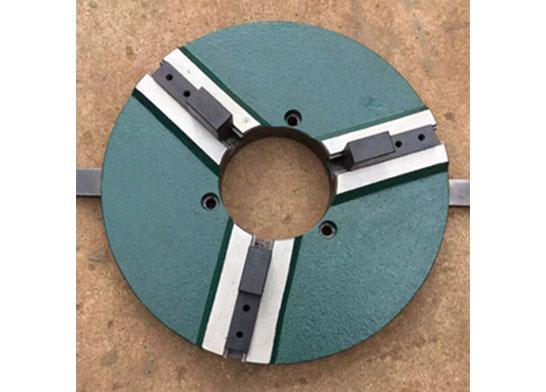

Attach Weldment Correctly

Splitting is a concern because the technique by which a weld is attached to a positioning device is as essential as the positioner themselves. Manufacturing fixtures are created for a certain program that is used repeatedly. This fixture is permanently attached to the positioner, and its distinctive form allows for precise component alignment.

A 3-jaw chuck is commonly used to connect round components. While the element expands from the desk, the component must no longer shrink back from the jaws. Additionally, the element may grow or settle as a result of the heating and cooling that occurs during and after the welding method, which might cause the chuck's hold on the workpiece to change.

Many positioners have slots for bolting the workpiece to the face. Welding the component to the positioner is a good way to avoid shear forces from sliding the element while it is being moved. Any of those approaches, whether stand-alone or combined, will work if used correctly.

Remember The Cog

When choosing the right positioning device for the task, it's important to consider not only the weight and length of the weldment but also the center of gravity (cog) and how far it is from the site device. The cog factor is the value at which the weldment balances evenly on all axes. As the distance between the device and the positioner grows, more torque is applied to the positioner. Because the welder supplies the positioner with fabric and components, the cog changes, and these changes must be taken into account.

The motor and manual selection will be guided by the positioner manufacturer's specifications. Welders must examine the requirements for each horizontal and vertical loading to ensure that the weldment is capable of being addressed. The positioner must be able to withstand the maximum load possible.

Use Turning Rolls For Cylinders

A weldment can be rolled if it has a cylindrical shape. A pipe or vessel can be rotated using small turning wheels or idlers to allow for down and welding. The power rolls produce a good circumferential weld by providing constant rotation. Although loafer rolls are not driven, they can be provided in a sequence to help with longer pipelines and containers. These are commonly used to connect pipes and ends to vessels and to add flanges to pipe ends.

When a spherical component is extended outward, the combination of a roller-type pipe stand and a vertical-faced table positioner provides stability and safety. The weight is transported haphazardly, the cog may be supported, and the rollers provide two points of contact.

Join Ground Modern-Day To The Positioner

During welding, a ground modern must be connected to the positioner. The floor now moves from the table to the chassis, eliminating the need to remove and replace a welding clamp on a regular basis. Electric components may be damaged and poor weld deposits may be formed if adequate grounding is not provided.

The positioner must be compatible with the electrical current generated by the welding equipment. Additionally, all ground cables should be firmly secured by removing any paint before bolting to the carriage.

Keep It Flat

Despite the tiny positioning device, the unit must be set up on a flat, level surface to avoid tipping. If mounting holes are provided, these should be utilized to secure the positioner to a solid floor to prevent it from tipping over while in operation or if it is subjected to unusual pressure. A positioner mounted on a workstation or stand must also be securely fastened.

A Short Discussion On The Running Of Industrial Weld Positioners

A weld positioner's functioning principle is the same for all workpieces, no matter how large or tiny. They form a rotating plane that is perpendicular to the ground. Large pieces of tooling might be placed on those positioners. A welding positioner, on the other hand, is more than just a revolving workstation. Its performance is limited by the static torque output limitations. It was capable of rotating at high speeds while carrying a substantial amount of weight.

How Does A Welding Positioner Function?

Welding positioners function by grasping a pipe junction or valve and rotating the workpiece as needed, allowing the welder to continuously solder a flat joint with no breaks in the process. Instead of needing to reposition the torch or electrode-holder, the welder may maintain the weld puddle in place.

Welding positioners are useful for boosting welding deposition rates and lowering rejection rates because they make the welding seams on the pipeline more accessible. A welding gripper, also known as a welding positioner, helps the operator weld at quicker speeds than a manual or semiautomatic welding setup allows.

A welding positioner is a tool that keeps the comfort of the welder in mind. It makes them feel less tired since they can stand in one place and complete their work. They shouldn't move or bend since this welding positioner may revolve in 360 degrees. On the welding positioner, the objector painting piece to be welded is adjusted. Pipe joints or valves are used to outfit weld positioners. That is one of the main reasons why it is widely used in industries that form metal parts or components using metal fabrication or CNC machining. This article goes through the functions, advantages, and uses of weld positioners, among other things.

-

Q: How about the price of Fengwei welding manipulator?

A:Fengwei welding manipulator is mainly composed of operating device, control device, power source device, and process guarantee device. Its price will generally be quoted according to the parameters required by the customer. Our quotations will generally satisfy our partners, and we not only have certain advantages in terms of price, but we have also received praise from dozens of countries in terms of service.

Welding manipulator at work

Fengwei Machinery is a professional and high-quality welding automation manufacturer. For every product produced, Fengwei will be responsible for its pre-sales to after-sales. Therefore, if the price is similar, if Fengwei becomes a partner, It has gained a trust and guarantee. During the entire sales process, partners also need to bear the cost of ocean freight, but we must know that our ocean freight is the cheapest. We find a fast shipping team for our partners and preferential prices, but in general, ocean freight The price is also transparent, and Fengwei guarantees that we will give certain subsidies to the machine when the ocean freight is too high.

In terms of products, each machine contains a set of wearable parts, and we guarantee that our sold welding operation machines have a one-year warranty. Within one year, if the machine has non-human damage, Fengwei’s engineer team will Solve and deal with it as soon as possible, and the partner does not need to pay any fees. Outside the warranty period, don’t worry, Fengwei Machinery will provide certain solutions based on the damage of the machine, and the price will also be very favorable.

We support free installation of the machine and free guidance. Generally speaking, if you don’t know much about the welding operation machine, our engineers will give a one-to-one explanation, and use telephone voice, video, offline guidance and other forms.

-

Q: What are the after-sales of equipment like welding rotator?

A:Different equipment, we still have some differences in after-sales service. Take the welding rotator as an example. For example, when the machine involves customization or other requirements, we will communicate well with the customer in advance when it is delivered, and may add some customized services. After-sales service, but each machine of our after-sales service will include 12 hours of timely processing. Due to the time difference of individual countries, we often need to make a time difference, but we will be the first time we receive the user’s demand. Quickly solve such problems.

Generally speaking, the usage of our machines is still very good, not only within the one-year warranty period, there will be no problems (except for some consumable materials), this is still recognized by 20 countries from all over the world. Almost every machine is equipped with one or more sets of vulnerable parts.

Customers do not have to worry about the use of the machine. We not only have detailed instructions, and each customer will have a one-to-one professional engineer. You can communicate with our engineer at any time by email, phone, video, etc., and he will Solve the problem for you in a timely manner.

If the machine has a serious failure, we will set up an expert group as soon as possible, and will solve your problem within three days, not only that, our engineers will also give a detailed report for your future use, to eliminate such problems The second time the problem occurred.

Many people may be worried about the problem I mentioned above. Is it only the welding rotator? No, the above mentioned is included in all of our Fengwei machinery, including welding positioner, welding rotator, etc. We will have additional after-sales service for some high-quality customers or customized machines. These are all in our When the contract is signed, it is notified in advance.

-

Q: I am using a welding rotator urgently. How soon will the goods arrive?

A:Generally speaking, we will have the stock, our delivery time will be within 7 working days, of course, our own machine is different, our delivery time will also be adjusted, including custom-made machines, like a welding rotator. This machine involves multiple data tests and performance tests by our engineers. There may be a certain time extension, but generally we will guarantee it within 7 working days.

When there is no stock, our cycle needs to be adjusted, usually one month, because some customized models are also not available in stock. Different parameters and power may cause the delay of production. Of course, our engineers will give you the first time Out the corresponding delivery time.

The time for the buyer to receive the goods is not fixed. It mainly depends on the policies and distances of the two countries of the shipping. You need to know the country to give the time.

-

Q: How can I know the consumable materials of welding rotator?

A:We all have detailed instructions on the consumable materials of welding rotator, so customers don’t have to worry about this. Not only that, Fengwei has an explanation on this point for each machine or production line. When buying a machine, Fengwei also Provide a set of accessories for consumable materials to ensure the accuracy of machine operation in the future.

If you still have any questions, please know that the list of vulnerable parts will be marked in the box list, which can be checked at any time. You can also call our one-to-one engineers, and you can consult the details of the machine at any time.

When the spare parts have been used or are out of the warranty period, don’t worry, call Fengwei Machinery anytime, anywhere, and we will provide you with spare parts in this area within 24 hours. Here is a small reminder: Remember to use it. Related parts and accessories shipped with the machine to prevent other parts from affecting the accuracy of the machine.

-

Q: How about the performance of Fengwei welding rotator ?

A:The quality of Fengwei's welding rotator is certified by international standards. Not only that, Fengwei also provides a one-year unreasonable warranty period. Users can contact our engineers when there is any non-human failure during use. , We will contact you within 24 hours and provide you with replacement parts or consumables for free.

Fengwei treats every customer sincerely. We provide customers with customized services. For example, when the welding rotator fails to meet the desired requirements, we will provide customization of product power and appearance color to meet the initial efficiency At the same time, it can also satisfy customers' vision and efficiency maximization, and provide the most detailed plan for the factory's production convenience.

-

Q: Can the body color of the welding rotator be customized ?

A:All of Fengwei's products can be customized, not just limited to welding rotator, according to user needs, we also provide corresponding design requirements, such as the color of the body and the color of our company's products. However, according to the corresponding requirements, we will also charge part of the customization fee, but the price will also be within a moderate range.

Not only that, we also provide the customization and fuselage of the whole production line of the factory. In order to fit and meet the needs of customers, Fengwei Machinery needs to obtain the color samples of the customers so that the colors are perfectly matched.

(0510)83695226

yiru.wang@wxfengwei.com

+86-139 1534 9938

(86)13915349938

русский язык

русский язык

EN

EN